JR West is ushering in a new era of railway maintenance with the introduction of advanced humanoid robots. This groundbreaking initiative is designed to address labor shortages and enhance safety standards across the company’s extensive railway infrastructure.

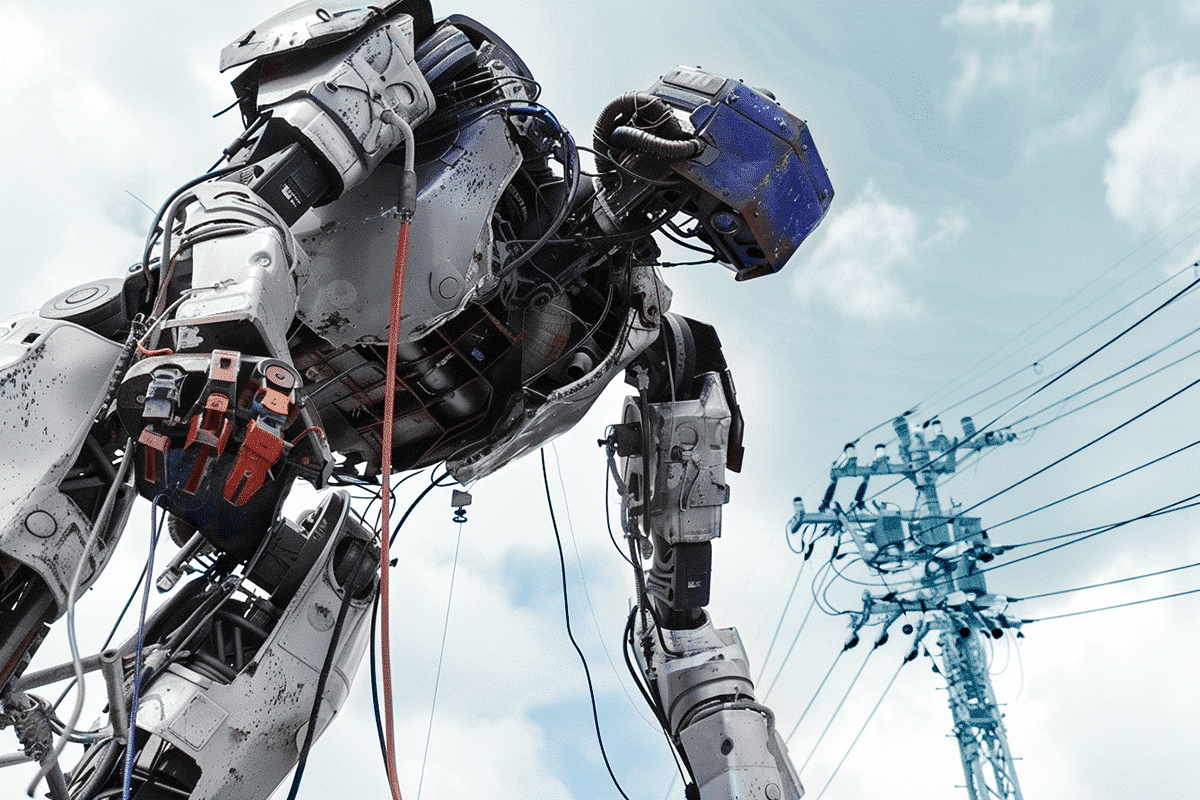

Starting this month, JR West will deploy giant Mecha-style robots to perform a variety of maintenance tasks. These include painting overhead support structures and removing tree branches that obstruct the tracks. These robots are not only large and powerful but also versatile, capable of lifting objects up to 40 kilograms (88 pounds) and reaching heights of up to 12 meters (39 feet). Equipped with a range of tools, these nimble-armed machines are set to handle numerous odd jobs that are crucial for maintaining the railway system’s integrity and safety.

The operation of these robots is a blend of advanced technology and human oversight. Each robot is controlled by a human operator who sits in an accompanying truck. Using a joystick and VR goggles linked to a camera mounted on the robot’s head, the operator can precisely direct the robot’s movements. This setup allows for detailed and accurate task execution, enhancing the efficiency and safety of the maintenance work.

A video demonstration of the technology in action showcases the robot’s capabilities, including wielding a circular saw to trim tall trees. This visual evidence underscores the safety and effectiveness of these robotic workers, alleviating any concerns about their reliability in handling such demanding tasks.

The development of this technology was a collaborative effort. JR West partnered with robotics company Jinki Ittai and tech company Nippon Signal to bring these advanced robots to life. The primary goals of this collaboration were to improve employee safety and reduce the risk of work-related accidents. By taking on physically demanding and potentially dangerous tasks, the robots help protect human workers from harm.

The introduction of these robots is also a strategic response to Japan’s significant labor shortages. With approximately 29 percent of the population over the age of 65, Japan faces a demographic challenge that affects many sectors, including railway maintenance. The aging workforce has led to a decline in available labor, causing economic strain. By employing robots to fill these gaps, JR West aims to alleviate some of this pressure and ensure that their railway system remains well-maintained and operational.

This innovative use of robotics highlights a different perspective on technology in the workplace. Often, robots and new technologies are criticized for displacing human workers. However, JR West’s approach demonstrates how they can be used to complement the workforce, particularly in scenarios where there are not enough human workers to meet demand. This strategy not only addresses immediate labor shortages but also sets a precedent for how advanced technology can be integrated into traditional industries to enhance efficiency and safety.

As JR West rolls out these humanoid robots, the company is poised to lead the way in modernizing railway maintenance. This initiative not only ensures the continued smooth operation of Japan’s railway system but also provides a glimpse into the future of industrial work, where human and robotic collaboration becomes the norm.